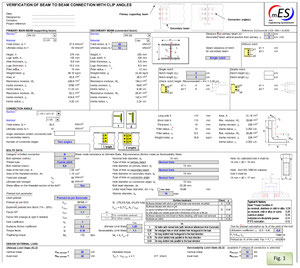

Clip angles connection

The spreadsheet verifies a connection between two horizontal H beams using clip angle sections.

The verification is perfomed considering the Eurocode norm EN 1993-1-8:2005.

Features:

- Sections database for beams and angle selection

- Possibility to insert User section for primary beam, secondary beam and clip angle

- Section characteristics evaluation (area, Inertia moments, Bending modulus resistances, centroid axis position)

- Possibility to introduce notches for the connected beam

- Possibility to choose one or two angles for the connection

- Standard steel and user defined materials

- Graphical representation of the joint

- Separate definition of the bolting configuration for the connection on secondary and primary beam

- Bolts definition (characteristics and geometry).

- Selection of connection category A, B, C, D and E as per Eurocode

- Bolts in shear or friction working mode

- Preload definition for bolts

- Graphical output of the bolting and clip angles configuration

- Ultimate and Serviceability Limit State design loads (shear and tension)

- Graphical output of forces on bolts

- Prying effect evaluation for bolts connected on primary beam

CHECKS FOR SUPPORTED BEAM SIDE

- Bolts shear resistance (individual bolt check from forces resultant)

- Bearing resistance of the web of the secondary beam (individual bolt check from forces resultant)

- Bearing resistance of the connection angles (individual bolt check from forces resultant)

CHECKS FOR VERTICAL SHEAR:

- Bolts shear resistance

- Bearing resistance of the connection angle

- Bearing resistance of the beam

- Shear resistance of the connection angle (gross section)

- Shear resistance of the connection angle (net section)

- Connection angles in shear (block tearing)

- Shear resistance of the web of the secondary beam (gross section)

- Shear resistance of the web of the secondary beam (net section)

- Beam web in shear (block tearing)

- Bending resistance of the secondary beam

CHECKS FOR HORIZONTAL TENSION

- Bolts shear resistance

- Bearing resistance of the connection angle

- Bearing resistance of the secondary beam

- Connection angles in tension (block tearing)

- Tension resistance of the beam (net section)

- Beam web in tension (block tearing)

- Tension resistance of the angle cleats in bending

- Friction bolt resistance (SLS or SLU) (individual bolt check from force resultant)

CHECKS FOR SUPPORTING BEAM SIDE

- Bolts shear resistance (individual bolt check from force resultant)

- Bolts tension resistance (individual bolt check from force resultant)

- Bolts combined tension and shear resistance (individual bolt check from force resultant)

- Bearing resistance of the web of the primary beam (individual bolt check from force resultant)

- Bearing resistance of the connection angles (individual bolt check from force resultant)

- Punching resistance of the web of the primary beam (individual bolt check from force resultant)

- Punching resistance of the connection angles (individual bolt check from force resultant)

- Bolts group verification

- Shear resistance of the connection angle (gross section)

- Shear resistance of the connection angle (net section)

- Connection angles in shear (block tearing)

- Friction bolt resistance (SLS or SLU) (individual bolt check from forces resultant)

The metric unit system (S.I.) is used.

The spreadsheet you will purchase and receive is an excel file compiled in a “.EXE” application file format identified by our icon image. See the Activation/Support page for more details.

Trial version

You can download a trial version of this spreadsheet for evaluation purpose. Click below to download the zipped file.

The trial version is fully working but with limited functions with respect to the complete version.

To activate it, unzip the downloaded file, run the application and insert the Activation Key you will find in the .TXT file.

To purchase the full version go back to this webpage.

The trial spreadsheet is fully working with the following limitations:

- Only one available section for the primary beam

- Only one available section for the secondary beam

- Only one available size and class for the bolt selection

- It is not possible to open/save external spreadsheets when it runs

- Excel toolbar is not visible

- Print function is disable

- Copy and paste functions are disable

- Save function is disable

What you will find in the full version

- Complete database for primary H section (European and british sections)

- Complete database for secondary H section (European and british sections)

- No limitation for bolt size and class

- It is possible to open/save external spreadsheets when it runs

- Excel toolbar is visible

- Print function is available

- Save function is available

- Copy and paste functions are available

For support and questions contact us.

Spreadsheet versions list:

Version 1.0: new introduced file.

Version 2.0:

Added additional verifications for the various elements.

Additional verifications for bolts with resistance calculation considered as group and as individual entities.

Added resistance of the angle cleats and secondary beam in bending.

Improved some calculations for gross and net sections.

For supported beam side the verifications have been separated for shear and tension effect.

Additional inputs introduced (washer size and L radius for angle bending verification).

Added length for the notched cases.

Restyling of the sheet and improving of the graphical output and results.

Minor bugs corrected.